Executive Summary

In the poultry industry, inventory is biological—it grows, consumes resources, and has a strict shelf-life. This pilot project successfully demonstrated that a Business Intelligence (BI) Decision Support System could aggregate siloed data streams to provide real-time visibility into stock levels, potentially reducing waste and optimizing feed conversion ratios.

Process Breakdown

1. Define

The Hypothesis: Can a biological inventory system be digitized for real-time tracking?

The client relied on manual logs for tracking stock. The disconnect between "Coop Data" (inventory) and "Point of Sale" (revenue) created a visibility gap. The goal was to build a prototype dashboard to prove that real-time data could solve this.

2. Measure

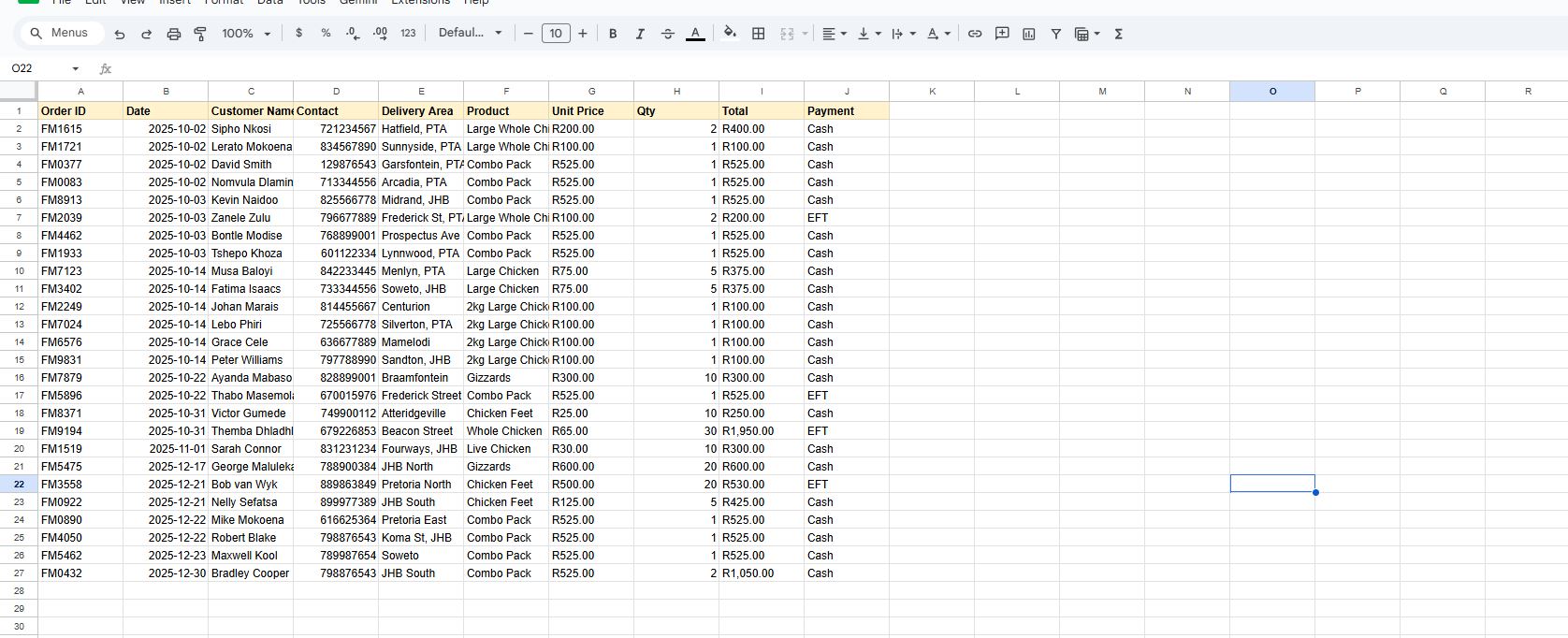

Figure 1: The Baseline - Disconnected Static Data

We audited the existing data landscape. The baseline measurement revealed:

- Latency: Reporting took 3-4 days to reach management.

- Fragmentation: Sales data was digital; Mortality data was analog (paper).

3. Analyze

The pilot exposed critical "dirty data" issues invisible in the manual system. We found that the primary bottleneck wasn't the software logic, but the operational discipline at the coop level.

"The analysis proved that while the software could handle the logic, the SOPs needed to be upgraded first."

4. Improve (The Pilot)

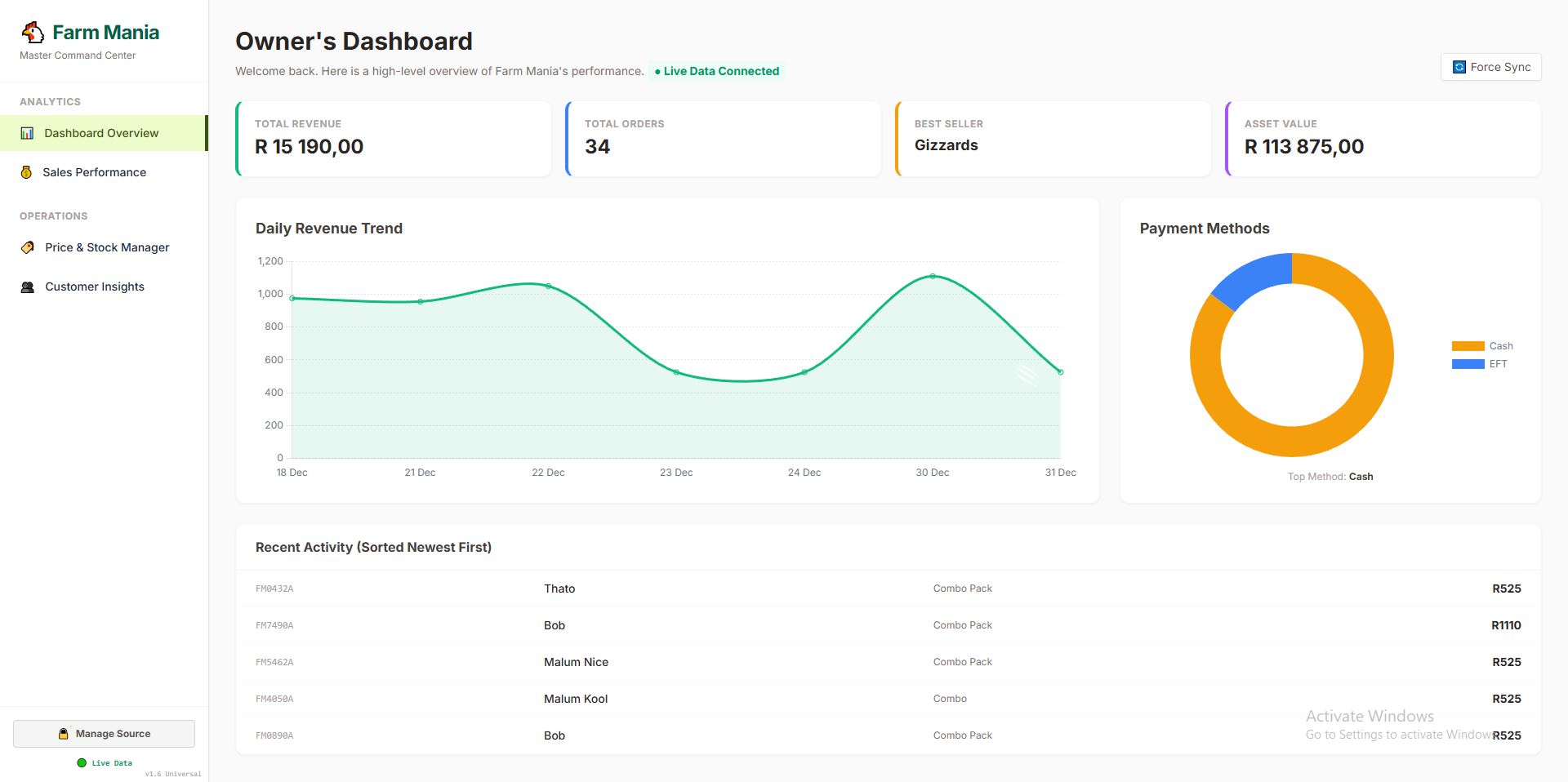

We engineered a Power BI Decision Support System to demonstrate the "Art of the Possible."

Figure 2: The Pilot - Live Inventory Dashboard

5. Control

The pilot concluded with a Feasibility Report. We handed over a roadmap for future readiness, recommending that data inputs be standardized (SOPs) before scaling the tool to ensure data integrity.

Need a Digital Nervous System?

Automania helps businesses bridge the gap between legacy operations and modern automation.

Book a Consultation