The Compliance Challenge

For a Civil Engineering Laboratory, accreditation is survival. Under ISO 17025, labs must demonstrate competence in testing (e.g., concrete cube crushing strength) and calibration.

The Audit Gap: The standard explicitly requires a formal process for handling customer complaints and feedback. Most labs fail here, relying on ad-hoc emails that get lost before an audit.

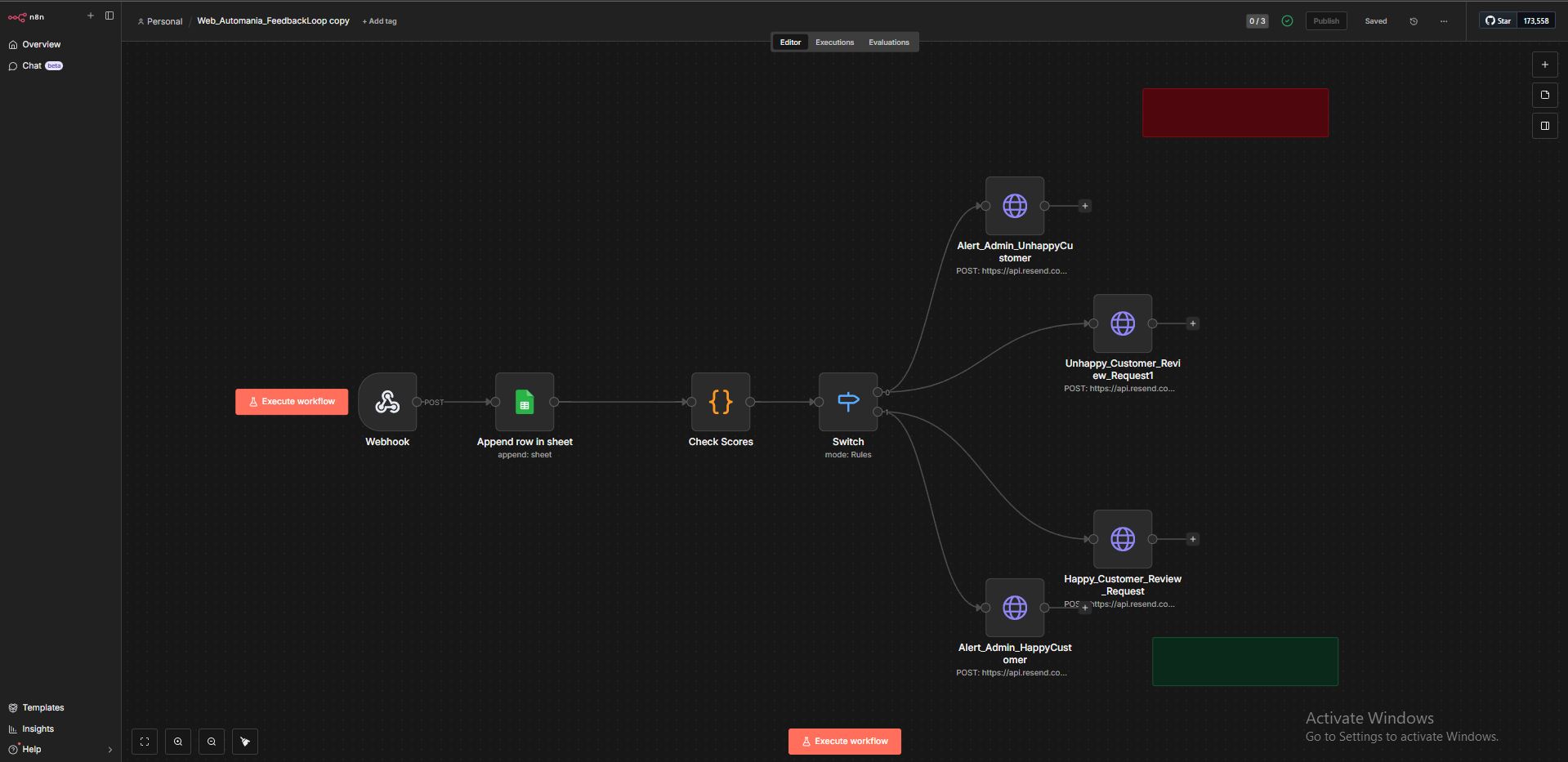

The Solution: We engineered a "Feedback Interceptor"—a digital Quality Management System (QMS) that gathers audit-ready data and triggers immediate corrective action (CAPA) for bad reviews.

The PDCA Cycle Implementation

1. Plan (The Standard)

Objective: Align Feedback Collection with ISO 17025.

The plan was to create a digital "listening post" that integrates with the lab's reporting cycle. We defined the criteria for a "Non-Conformance" (e.g., late results, incorrect calibration certificates) and designed the workflow to capture this data automatically.

2. Do (The Interceptor)

Upon issuing a Concrete Cube Test Report, the system triggers a feedback request. This is not just a survey; it is a Digital Audit Trail.

Figure 1: The testing environment where compliance is critical.

3. Check (The Logic Gate)

Innovation: Real-time Filtering.

The system acts as a firewall for the lab's reputation and accreditation status. It "Checks" the incoming data against the Quality Threshold:

- Compliance Check: Is the client satisfied with the testing accuracy?

- Service Check: Were the results delivered on time?

4. Act (Corrective Action)

The system automates the Corrective Action Preventative Action (CAPA) workflow, splitting feedback into two streams:

Action: Routed instantly to the Quality Manager.

Outcome: Immediate root cause analysis.

Action: Logged as "Evidence of Customer Satisfaction".

Outcome: Verified compliance for SANAS audit.

Is Your Lab Audit-Ready?

We build automated Quality Management Systems that ensure ISO 17025 compliance while protecting your reputation.

Book a Systems Consultation