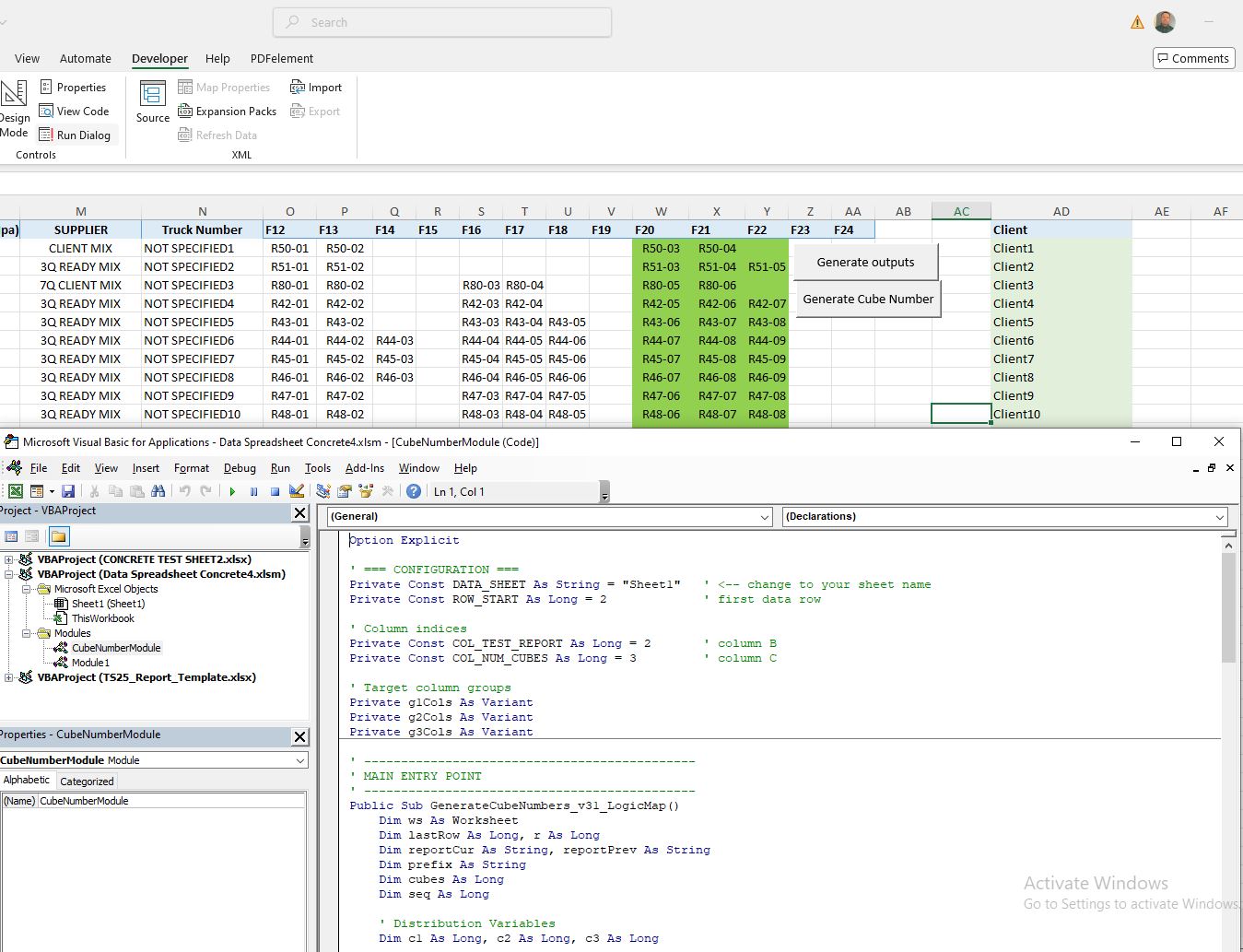

The "Excel Hell" Bottleneck

In many operations, the bottleneck isn't the machinery—it's the administration. Companies often rely on "Legacy Systems" (older ERPs or spreadsheets) that require hours of manual copy-pasting to generate reports.

The IE Perspective: This is Non-Value Added (NVA) activity. It increases Cycle Time and introduces Defects (human error).

The Solution: We deploy lightweight VBA Automation to bridge the gap. We don't replace the system; we turbocharge it.

Targeting The 8 Wastes (TIMWOODS)

Waste: Waiting

Before: Staff waiting 4 hours/week for reports to be compiled manually.

After: Report generates in 3 seconds.

Waste: Defects

Before: Manual entry led to data discrepancies and "fat finger" errors.

After: Poka-Yoke (Mistake Proofing) via validated input forms.

The "Under the Hood" Engineering

Figure 1: Custom VBA Algorithms replacing manual data manipulation.

Is Your Team Stuck in Spreadsheets?

Stop paying talented staff to do data entry. Automate the mundane so they can focus on the meaningful.

Request an Automation Audit